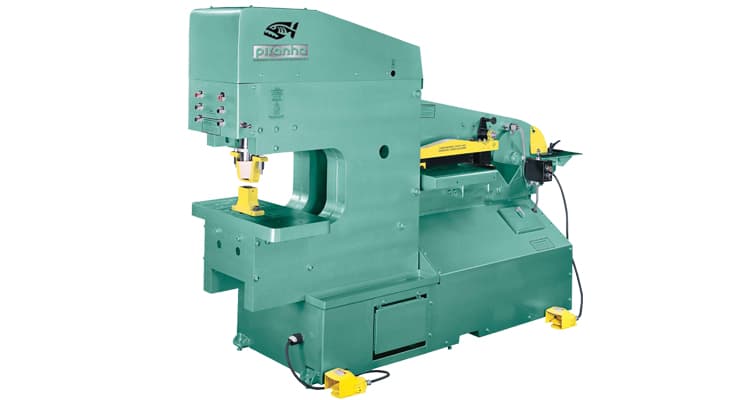

Piranha Iron Worker Machines Diagram

Piranha Single Operator Ironworkers are capable of performing most tasks. When two simultaneous operations are needed (e.g. You should consider a dual operator ironworker if two simultaneous operations are required (e.g., punching and notching).

Whitney Single End Punch Presses and Piranha are opening the door to applications that require higher punching capabilities, larger sheets, or deeper throats.